Fuselage

TTP

|

B1-L3

|

ATA53

|

Cessna

172

|

B2-L1

|

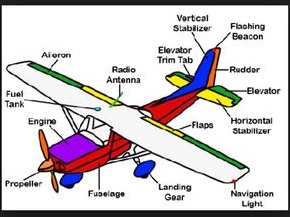

Fuselage - semimonocoque construction and consists of three major sections: forward section, center section, and tailcone section. Construction consists of formed bulkheads, longitudinal stringers, reinforcing channels and skin. Frame members of the cabin section are constructed of formed bulkhead channels. Bulkheads are formed "U" channel sections. Principal material is 2024- 0 alclad aluminum alloy which, after forming, is heat treated to a 2024-T42 condition and painted with epoxy primer. All bulkheads in the fuselage are constructed of formed sheet metal or reinforced sheet metal.

Wings are of all-metal, strut-braced, semi

monocoque construction, utilizing two spars. Each wing consists of an outer

wing panel with an integral fuel bay, an aileron and a flap. Flanged upper and

lower edges of all ribs serve as cap- strips, in addition to providing rigidity

to the rib. The skin, riveted directly to each rib flange, provides the

cellular strength for each successive rib bay.

Nose, center, and trailing edge rib

segments are riveted together through the front and rear spars to form the

basic airfoil sections.

Alclad

stringers stiffen the skin between ribs. Spars are comprised of machine milled,

tapered extrusions riveted to sheet metal webs.

Stabilizer full-cantilever, all- metal tail group

consists of a vertical stabilizer and rudder, and a horizontal stabilizer and

elevators. The horizontal stabilizer is of one-piece construction, consisting

of spars, ribs and skins. Elevators are constructed of aluminum spars, ribs and

skin panels. The skin panels are riveted to ribs and spars. A balance weight is

located in the outboard end of each elevator, forward of the hinge

line.

Elevator trim tab, attached to each elevator, is constructed of a spar, ribs,

and skin; all riveted together. The vertical stabilizer is constructed of a

forward spar and aft spar, ribs and skin. The rudder is constructed of spars,

ribs and skin panels. The rudder trim tab is constructed of a spar, ribs, and

skin; all riveted together.

Main landing gear is constructed of 6150 alloy spring-steel tubing with

attaching parts of high strength 7075-T73 aluminum alloy forgings.

Nose gear components are 4130, 6150 alloy steel and 7075-T73 aluminum alloy forgings.

Nose gear components are 4130, 6150 alloy steel and 7075-T73 aluminum alloy forgings.

Engine mount is constructed of welded 4130 steel tubing.

Engine cowling consists of upper and lower

formed aluminum sections. The upper section includes and oil inspection door,

and the lower section includes an air induction scoop with an engine oil

filter. Both sections are removable.

531001 Fuselage Surface - Inspect for skin damage,loose rivets, condition of paint, and

check pitot-static ports and drain holes for obstruction. Inspect covers and fairings for security.B 05-12-01 210

531002 Firewall Structure - Inspect for wrinkles, damage, cracks, sheared rivets, etc. Check

cowl shock mounts for condition and security.

531003 Internal Fuselage Structure - Inspect bulkheads, doorposts, stringers, doublers, and

skins for corrosion, cracks, buckles, and loose rivets, bolts and nuts.

531017 Areas of the cabin structure. inspect these areas: 1. Cabin door forward

and aft frames. 2. Window frames with emphasis at stringers and channel assemblies

from aft of door frame to aft bulkhead. 3. Seat attachment structure. 4. Aft

Cabin Bulkhead.

Comments

Post a Comment